Five important trends for the robotics industry in 2023

Robot installations hit a record high in 2021, according to the data. More than 50,000 new industrial robots were installed that year. According to AdvancingAutomation(A3) Associates, robot sales in North America hit a record high in 2022 for the second year in a row, generating $2.3 billion in revenue.

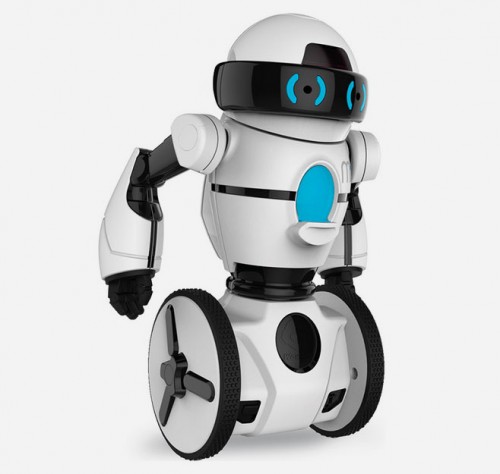

As more robots go out to work, it can be difficult to keep track of everything that is changing in such a fast-moving industry. Here are five important trends for the robotics industry.

1. Energy efficiency

Energy efficiency is the key to improving business competitiveness, as energy costs increase. The application of BCW31 robotics helps reduce energy consumption in manufacturing. A lot of energy can be saved by reducing heat compared to a traditional assembly line. At the same time, robots can work quickly, increasing productivity and saving more time and energy for manufacturing.

Today's robots are designed to consume less energy, thus reducing operating costs. To achieve sustainable production goals, the company uses industrial robots equipped with energy-saving technology: for example, robot controls can convert kinetic energy into electricity and feed it back to the grid. The technology significantly reduces the amount of energy needed to run the robot. Another feature is the smart energy saving mode that can control the robot's energy supply throughout the working day. Such connected power sensors are likely to become the industry standard for robotic solutions, as even today industrial facilities need to monitor their energy consumption.

2. Reflux

Flexibility has become an important incentive for industries to return: carmakers, for example, have invested heavily in short supply lines to bring the process closer to customers. These manufacturers use robotic automation to economically and efficiently mass-produce powerful batteries to support their electric vehicle projects. These investments make shipping heavy batteries redundant. This is important because more and more logistics companies are refusing to ship batteries because they are safe.

Moving microchip production to the United States and Europe is another returning trend. Proximity to customer supplies is important because semiconductor chips are needed for most industrial products. Robots play a crucial role in chip manufacturing because of their ability to meet extreme precision requirements.

Specially designed robots automate silicon wafers, take over cleaning tasks or test integrated circuits. The most recent example of backflow is a new Intel chip plant in Ohio, or Wolfsped and automotive suppliers, which recently announced the use of a chip plant run by EF in Saarland, Germany.

3. Make robots easier to use

Robots are easier to program and non-experts are easier to get started. Software-driven automated platform vendors support companies that allow users to manage industrial robots without programming experience. Original equipment manufacturers work with low-code or even no-code technology partners to allow users of all skill levels to program robots.

Easy-to-use software combined with an intuitive user experience has replaced extensive robot programming, opening up new opportunities for robot automation: software startups are entering the market to provide specialized solutions to meet the needs of smes. Traditional heavy-duty industrial robots, for example, could be equipped with sensors and new software that allow collaborative setup and operation. In this way, workers can easily adjust heavy machines to complete different tasks. As a result, companies will have the best of both worlds: powerful, accurate industrial robot hardware and state-of-the-art cooperative robot software.

Easy-to-use programming interfaces that allow customers to set up their own robots are also boosting the emerging field of low-cost robotics. Many new customers try robotic solutions to deal with the 2020 pandemic. Robot vendors acknowledge this need: ease of setup and installation, for example, using pre-configured software to handle clamps, sensors or controllers to support low-cost robot deployment. These robots are usually sold in online stores, and programs and programs for various applications can be downloaded from the app store.

4. Artificial Intelligence (AI) digital automation

As digital technology advances, robot suppliers and system integrators are providing new applications to improve the speed and quality of existing applications. Internet robots are transforming manufacturing. Robots will increasingly be used as part of the Internet's digital ecosystem: cloud computing, big data analytics or 5G mobile networks provide the technical foundation for optimizing performance. 5G standards will enable all digital production, making workshop cables obsolete.

Artificial intelligence (AI) robotics has huge potential to bring a range of benefits to manufacturing. The main purpose of using AI in robotics is to better manage variability and unpredictability in the external environment in real time or offline. This allows AI-enabled machine learning to play an increasingly important role in software products, benefiting visual capture-based optimization processes, predictive maintenance or operating systems.

The technology helps manufacturers, logistics providers and retailers deal with changing products, orders and inventory. The greater the variability and unpredictability of the environment, the more likely it is that an AI algorithm will provide cost-effective and quick solutions - for example, a manufacturer or wholesaler dealing with millions of different products that change regularly. Ai is also useful in environments where mobile robots need to distinguish between objects or people and react differently.

5. Second Life industrial robots

Industrial robots can have a service life of up to 30 years, and new technological equipment is a great opportunity for older robots to get a "second life." ABB, Fanuc, industrial robot manufacturers such as KUKA or Yaskawa have dedicated repair centers near their customers to refurbish or upgrade used equipment in an efficient resource manner. This strategy of preparing maintenance for robot manufacturers and their customers can also save costs and resources. Providing customers with long-term maintenance is an important contribution to the circular economy.

I prodotti a cui potresti essere interessato

|

AMI-21-60-6A | LINE FILTER 250VAC 60A CHASS MNT | 7416 More on Order |

|

AMI-29B-8-3 | LINE FILTER 110/250VAC 8A CHAS | 3078 More on Order |

|

AMI-27B-6-3 | LINE FILTER 250VAC 6A CHASS MNT | 6678 More on Order |

|

AMI-M11P-3-10-B-2 | LINE FILTER 250VAC 3A CHASS MNT | 2736 More on Order |

|

AMI-M11W1-1-3-B | LINE FILTER 250VAC 3A CHASS MNT | 5832 More on Order |

|

AMI-23A-10-3 | LINE FILTER 250VAC 10A CHASS MNT | 3366 More on Order |

|

AMI-23B-8-3 | LINE FILTER 250VAC 8A CHASS MNT | 4932 More on Order |

|

AMI-23A-4-3 | LINE FILTER 250VAC 4A CHASS MNT | 7146 More on Order |

|

AMI-23A-4-1 | LINE FILTER 250VAC 4A CHASS MNT | 4284 More on Order |

|

AMI-M11J-3-5-B-2 | LINE FILTER 250VAC 3A CHASS MNT | 4626 More on Order |

|

AMI-23-3-3 | LINE FILTER 250VAC 3A CHASS MNT | 3508 More on Order |

|

AMI-22A-10-3 | LINE FILTER 250VAC 10A CHASS MNT | 4032 More on Order |

|

AMI-22B-1-3 | LINE FILTER 250VAC 1A CHASS MNT | 5886 More on Order |

|

AMI-21-13-1 | LINE FILTER 250VAC 13A CHASS MNT | 3960 More on Order |

|

AMI-M11J-3-2-B-2 | LINE FILTER 250VAC 3A CHASS MNT | 3330 More on Order |

|

AMI-B11C-13-10-B-2 | LINE FILTER 250VAC 10A CHASS MNT | 6804 More on Order |

|

AMI-M32A-10-16-E-2 | LINE FILTER 16A CHASSIS MOUNT | 2826 More on Order |

|

AMI-27-36-6 | LINE FILTER 110/250VAC 36A CHASS | 6084 More on Order |

|

AMI-M12B-6-20-B | LINE FILTER 250VAC 20A CHASS MNT | 2754 More on Order |

|

AMI-22A-20-1 | LINE FILTER 250VAC 20A CHASS MNT | 8244 More on Order |

|

AMI-29B-1-1 | FILTER MULTI-STAGE HI PERFORM 1A | 2358 More on Order |

|

AMI-23B-6-1 | LINE FILTER 250VAC 6A CHASS MNT | 8424 More on Order |

|

AMI-21-12-1 | LINE FILTER 250VAC 12A CHASS MNT | 6570 More on Order |

|

AMI-M11A-3-5-D | LINE FILTER 250VAC 5A CHASS MNT | 6210 More on Order |